Leave Your Message

In the ever-evolving world of warehouse management, efficiency is paramount. As businesses seek ways to optimize their operations, the use of advanced tools such as the Motorized Pallet Jack has become increasingly essential. These innovative devices not only streamline the process of moving goods but also enhance safety and reduce labor costs in high-demand environments. In 2025, the benefits of employing a Motorized Pallet Jack will be more pronounced than ever, making it a vital asset for any warehouse aiming to improve its productivity.

As warehouses become busier and the demand for rapid distribution grows, the reliance on effective material handling solutions like the Motorized Pallet Jack will be critical. These machines allow operators to navigate tight spaces with ease, significantly reducing the physical strain associated with manual pallet handling. By incorporating the latest advancements in design and technology, the Motorized Pallet Jack is uniquely positioned to meet the challenges of modern logistics, ensuring that businesses can keep up with the fast-paced nature of supply chain demands.

In this article, we will explore the top five Motorized Pallet Jacks that are set to revolutionize warehouse efficiency in 2025. Each option offers unique features and capabilities that cater to various operational needs, setting the stage for a more productive and streamlined warehousing experience. As we delve into these top choices, it becomes clear that investing in a reliable Motorized Pallet Jack could be the key to unlocking unparalleled efficiency in any warehouse setting.

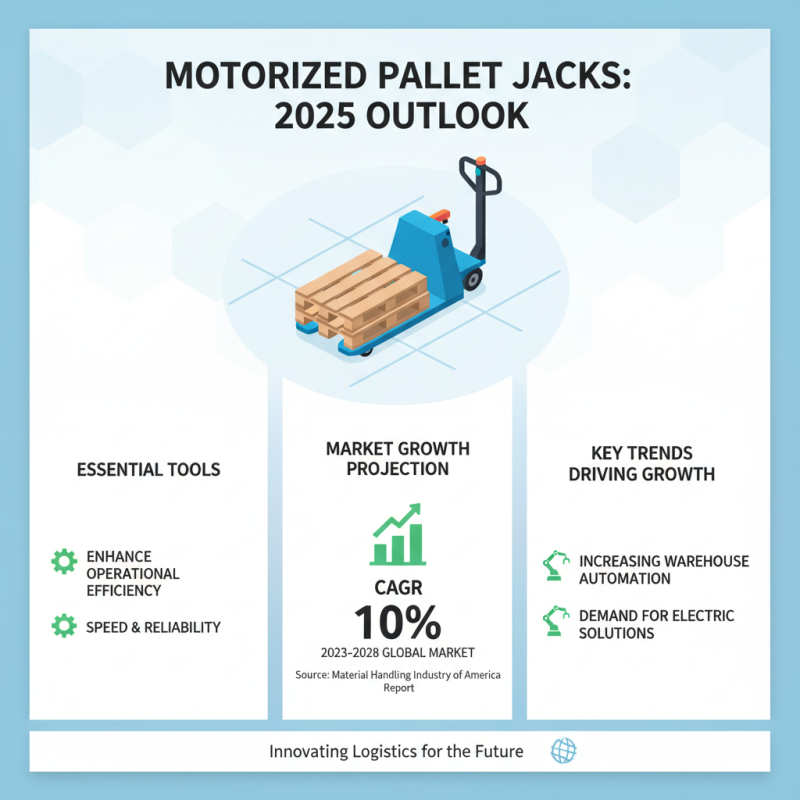

Motorized pallet jacks have increasingly become essential tools in modern warehouses, significantly contributing to operational efficiency. These electric devices are designed to facilitate the movement of heavy pallets with minimal human effort. By utilizing a battery-powered lifting and steering mechanism, motorized pallet jacks reduce the physical strain on operators and enable quicker transportation of goods across the warehouse floor. This enhancement in speed and ease of use leads to improved productivity, as workers can focus more on other critical tasks rather than the manual handling of materials.

Furthermore, motorized pallet jacks play a pivotal role in optimizing warehouse layout and inventory management. Their compact design allows them to maneuver in tight spaces, making it easier to access goods stored in less accessible areas. This flexibility not only maximizes space utilization but also minimizes the risk of damage to products and injuries to personnel. As warehouses evolve to meet the demands of fast-paced supply chains, incorporating motorized pallet jacks can significantly streamline processes and ensure timely deliveries, ultimately supporting business growth and customer satisfaction.

| Model | Load Capacity (lbs) | Battery Type | Weight (lbs) | Max Lift Height (inches) | Runtime (hrs) |

|---|---|---|---|---|---|

| Model A | 5500 | Lithium-ion | 450 | 7 | 8 |

| Model B | 5000 | Lead Acid | 550 | 6 | 6 |

| Model C | 6000 | Lithium-ion | 430 | 8 | 10 |

| Model D | 7000 | Lead Acid | 600 | 7 | 5 |

| Model E | 5500 | Lithium-ion | 480 | 8 | 9 |

When selecting a motorized pallet jack for your warehouse needs, there are essential features to consider that can significantly enhance efficiency. First, look for a model with a robust lifting capacity. Ensure that it can handle the weight of your typical loads, as this will directly impact your workflow. Additionally, a pallet jack with adjustable forks can accommodate various pallet sizes, offering versatility in handling different goods.

Battery life is another critical feature. A long-lasting battery ensures that the pallet jack can handle multiple shifts without frequent recharging, which minimizes downtime and maximizes productivity. Consider options with quick-charging capabilities for added convenience. Moreover, an intuitive control system can simplify operation, allowing workers to navigate tight spaces with ease and enhancing overall safety in the warehouse environment.

**Tips:** When assessing motorized pallet jacks, prioritize models with safety features like automatic braking systems and ergonomic designs that reduce strain for operators. Also, take note of maintenance requirements; selecting a model with easily accessible parts can save time and reduce repair costs in the long run. By focusing on these key features, you can make an informed decision that boosts your warehouse efficiency.

In the fast-paced world of warehousing and logistics, motorized pallet jacks have become essential tools for enhancing operational efficiency. As we look towards 2025, a variety of top brands and models are setting the standard for performance and reliability. According to a recent industry report by the Material Handling Industry of America, the global market for electric pallet jacks is anticipated to grow at a CAGR of 10% over the next few years, driven by increasing demand for automation in warehouses.

Among the leading models projected to dominate the market are those that feature advanced battery technology, offering longer operational time and faster charging capabilities. Innovations such as integrated smart technology allow for weight sensing and load monitoring, significantly reducing the margin of error in inventory management. The Enhanced Energy Efficiency Initiative report emphasizes that warehouses employing modern motorized pallet jacks can see a reduction in operational costs by up to 20%, demonstrating the economic advantages of upgrading equipment.

Furthermore, safety and maneuverability remain priorities in the design of these machines. Many new models are equipped with ergonomically designed handles, intuitive controls, and advanced stability features, ensuring a safer working environment for warehouse staff. A study by the National Safety Council highlights that improved equipment design can lead to a 30% decrease in workplace accidents, reinforcing the importance of investing in high-quality motorized pallet jacks to not only boost efficiency but also protect employees. With these advancements, businesses can look forward to a more productive future in warehouse operations.

As warehouses continue to evolve to meet growing demands, the efficiency of material handling equipment like motorized pallet jacks plays a critical role. Recent industry reports highlight that implementing motorized pallet jacks can lead to a 30% increase in productivity, significantly reducing the time spent on transporting goods. This is particularly crucial in fast-paced environments where every second counts. A comparison of different models reveals that while some may have a higher upfront cost, their durability and efficiency can translate into lower long-term operational expenses.

When evaluating motorized pallet jacks, functionality such as lifting capacity, battery life, and ergonomics must also be considered, as these features directly impact operational efficiency. According to a 2023 logistics and materials handling study, the average lifespan of a well-maintained motorized pallet jack is about 7 to 10 years. Models that offer easy maneuverability not only enhance worker productivity but also contribute to a safer working environment, thereby reducing the risk of accidents. Moreover, advancements in battery technology have improved energy efficiency, allowing some models to operate up to 10 hours on a single charge, further emphasizing the importance of choosing the right equipment for improving warehouse operations in 2025.

This chart compares five different motorized pallet jacks based on their cost, efficiency (load capacity), and functionality (features). Each model is evaluated to help warehouse managers make informed decisions regarding their investments.

Proper maintenance of motorized pallet jacks is essential to ensure their longevity and optimal performance in the warehouse setting. Regularly checking the battery and keeping it charged is crucial, as this not only ensures the equipment is ready for use but also extends the life of the battery itself. Additionally, it’s important to inspect the wheels and forks for wear and tear. Any signs of damage should be addressed immediately to prevent further issues that could result in costly repairs or operational downtime.

Another key aspect of maintaining motorized pallet jacks is performing routine cleaning and lubrication. Dust and debris can accumulate on the moving parts, which could hinder performance and lead to premature wear. By regularly cleaning the components and applying appropriate lubricants, you can ensure smooth operation and reduce the risk of mechanical failure. Furthermore, it’s advisable to keep an eye on the hydraulic fluids, making sure they are at the correct levels and free from contamination. This proactive approach not only enhances the efficiency of the pallet jacks but also contributes to a safer working environment.