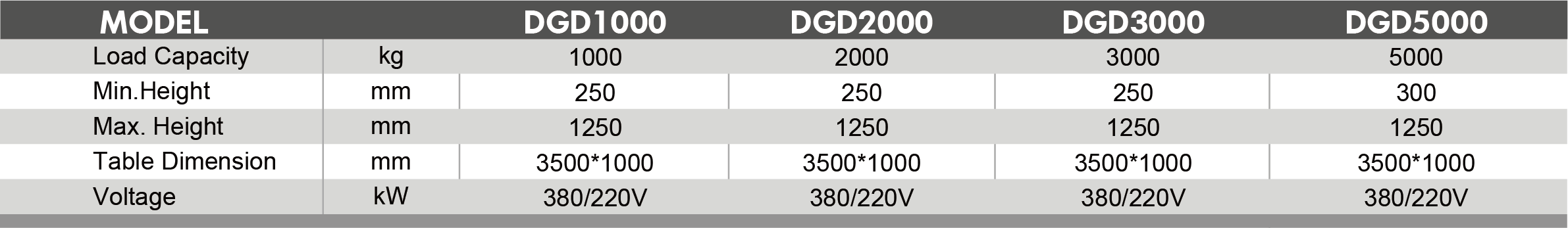

DGD Stationary Lift Table

Stationary lift tables, also referred to as scissor lift tables, are essential tools in various industrial and commercial settings, designed to facilitate the lifting and lowering of heavy loads. These robust platforms are engineered to provide stability and safety while enhancing productivity in tasks such as assembly, production, and maintenance.

One of the primary advantages of stationary lift tables is their capability to elevate heavy equipment, materials, containers, and objects to ergonomic heights. This feature is crucial for reducing strain on workers and improving efficiency in repetitive tasks that involve lifting and positioning items. By raising loads to comfortable working heights, these tables contribute significantly to ergonomic workplace practices, thereby minimizing the risk of injuries and enhancing overall operational efficiency.

The design of stationary lift tables typically involves a scissor mechanism, which enables vertical movement. This mechanism is powered by hydraulic, electric, or pneumatic systems, depending on the specific application requirements. Hydraulic systems are known for their robustness and ability to handle heavy loads efficiently, while electric systems offer precise control over lifting operations. Pneumatic systems, on the other hand, provide quieter operation and are suitable for environments where noise levels need to be minimized.

In industrial environments, stationary lift tables find applications across various sectors, including manufacturing, warehouses, distribution centers, and automotive facilities. They are used to facilitate processes such as loading and unloading trucks, assembling components, positioning materials at workstations, and transferring goods between different levels of a facility. Their versatility and capacity to handle substantial weights make them indispensable in industries where efficient material handling is critical to operational success.

Safety features are integral to the design of stationary lift tables to ensure the protection of operators and prevent accidents. These features may include safety rails, toe guards, emergency stop buttons, and overload protection systems. Regular maintenance and inspections are essential to uphold these safety standards and ensure the reliable performance of lift tables over time.

In conclusion, stationary lift tables play a pivotal role in modern industrial and commercial operations by providing a stable and efficient means of lifting heavy loads. Their ergonomic benefits, coupled with their safety features and versatility, make them indispensable tools for enhancing productivity and promoting a safe working environment. As industries continue to evolve, stationary lift tables will remain essential equipment for optimizing material handling processes and improving overall operational efficiency.

Hand Pallet Trucks

Hand Pallet Trucks Special Pallet Trucks

Special Pallet Trucks Galvanized and Inox Series

Galvanized and Inox Series Easy Lift Service

Easy Lift Service Manual Stackers

Manual Stackers Electric Pallet Truck

Electric Pallet Truck Electric Stackers

Electric Stackers Lift Table

Lift Table Drum Handling

Drum Handling Others

Others