WH-20/25SS Stainless Weighing Scale Pallet Truck

The STAXX Stainless Steel Weigh Pallet Truck is a highly efficient industrial equipment that combines weighing and handling functions, particularly suitable for environments where frequent weighing and handling of goods is required, such as food processing plants, pharmaceutical plants and chemical plants. Below are some detailed descriptions of this equipment.

High Precision muti-function LED screen

7 function keys, simple and convenient operation. 6-digit 32mm LED display, 7 state indicator lamps. Long service life and shock resistance.

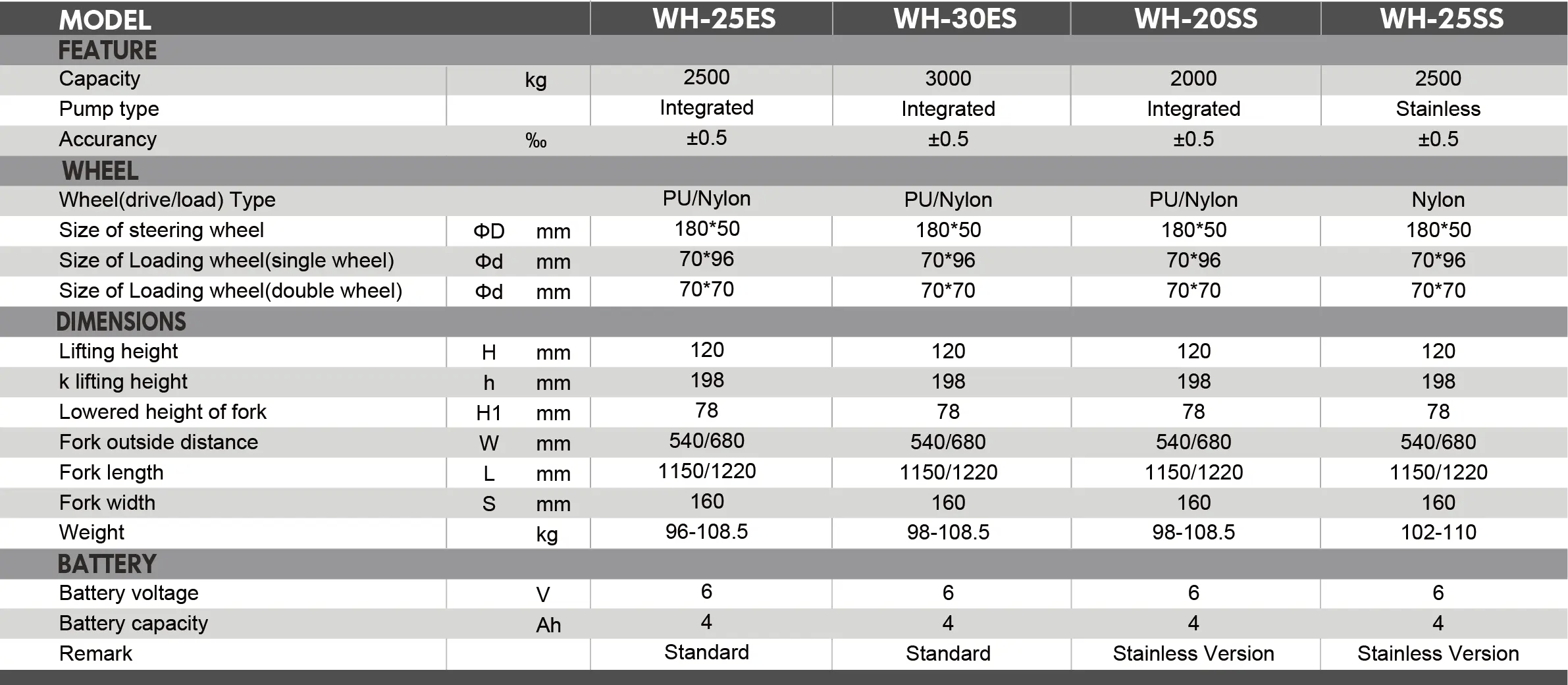

Accurate weighing up to 2000/2500kgs

Up to 2000kg or 2500kg, readings in kg or lb. 4 built-in load cells ensured accuracy. Accuracy ±0.5‰(500g)

Printer Option

Built-in printer with rich printing formats and communication protocol.

Corrosion resistant: The whole pallet truck is made of stainless steel, which has strong corrosion resistance and is suitable for use in humid and corrosive environments.

Easy to clean: Stainless steel surface is smooth, easy to clean and maintain, meets strict hygiene requirements.

Built-in weighing system: HIGH ACCURACY WEIGHING: Built-in load cell and display can provide accurate weight readings in real time, the error range is usually within ±500g to ensure the accuracy of weighing.

Convenient operation: the display is usually designed on the handle, allowing the user to easily view the weight reading, and some models are equipped with various weight unit conversion and totalization functions.

High load capacity: Stainless steel weighing pallet trucks usually have a high load bearing capacity, usually around 2.0/2.5 tons, which is suitable for handling and weighing heavy loads.

Electronic indicator with 32mm high red LED display. Four load cells ensure accurate readings in kg or lb. Long life internal battery. Rechargeable 6V/4Ah battery, 40 hours operation.

Sturdy and durable: The use of high strength stainless steel material ensures the durability and reliability of the pallet truck in long time and high frequency use.

Long-life design: High-quality hydraulic system and ball bearings ensure long life and stable performance of the equipment.

High quality wheels: Equipped with wear-resistant polyurethane wheels that minimize damage to the floor while providing smooth, quiet movement.

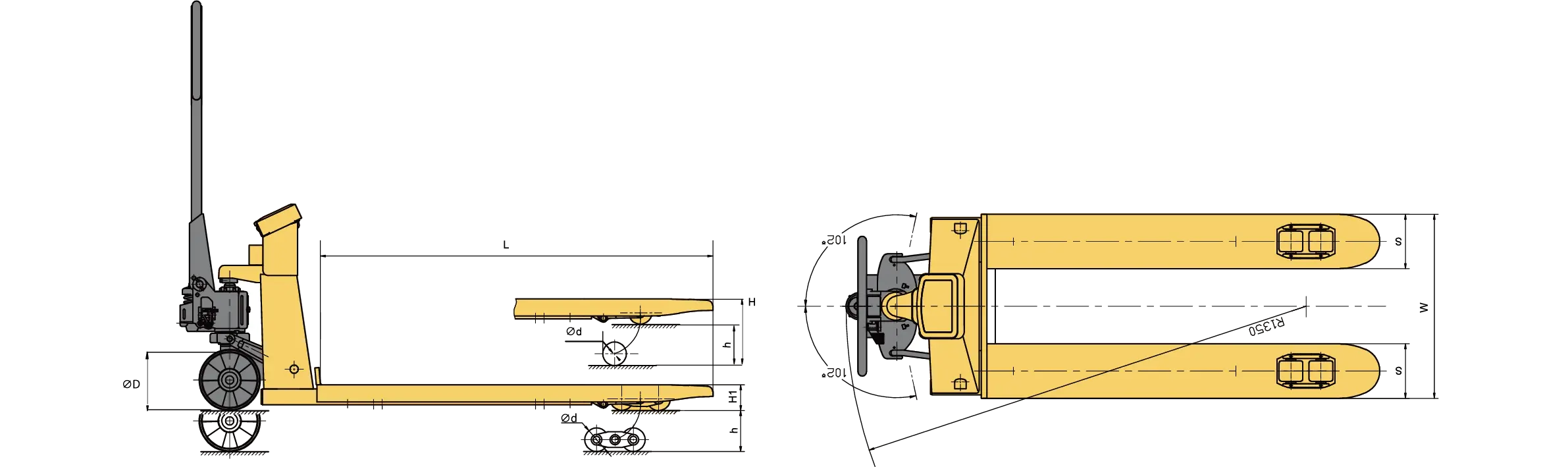

FLEXIBLE STEERING: Designed with a flexible steering system to ensure that the pallet truck can be maneuvered flexibly even in tight spaces.

Safe Design:

Overload Protection: Equipped with overload protection to prevent equipment damage and safety hazards caused by overloaded use.

Anti-leakage design: The hydraulic system is designed with anti-leakage function, which further improves the safety and reliability of use.

Application Scenario: Food processing plants: stainless steel material meets food safety standards and prevents contamination.

Pharmaceutical plants: Suitable for clean environments to prevent chemical corrosion and contamination.

Chemical plants: corrosion-resistant design suitable for handling a wide range of chemicals and corrosive substances.

STAXX stainless steel weighing pallet trucks significantly increase work efficiency and reduce operational steps by combining high precision weighing functions with efficient handling capabilities, and are widely used in industries with strict requirements for hygiene and weighing accuracy.

Hand Pallet Trucks

Hand Pallet Trucks Special Pallet Trucks

Special Pallet Trucks Galvanized and Inox Series

Galvanized and Inox Series Easy Lift Service

Easy Lift Service Manual Stackers

Manual Stackers Electric Pallet Truck

Electric Pallet Truck Electric Stackers

Electric Stackers Lift Table

Lift Table Drum Handling

Drum Handling Others

Others